Smart

Manufacturing

We are advancing the future of manufacturing by integrating Industry 4.0 and 5.0 principles, where cyber-physical systems, AI-driven automation, and human-machine collaboration redefine productivity and innovation.

Target: Zero-Defect

Our research focuses on smart product design and intelligent manufacturing systems that are highly interoperable, transparent, and adaptive to novel and extreme applications. We develop next-generation production technologies that enhance efficiency, performance, and sustainability through digitalization, waste reduction, and advanced materials.

Key areas include hybrid manufacturing (additive and subtractive processes), large-scale 3D printing (multi-material, freeform surfaces, recycled and abrasive materials, extreme environment applications), intelligent tool and process inspection, laser cladding, lean manufacturing, knowledge-based modeling, and topology optimization. By leveraging cyber-physical systems and AI-powered automation, we drive the transition to a smarter, more resilient, and sustainable manufacturing ecosystem.

Related Projects

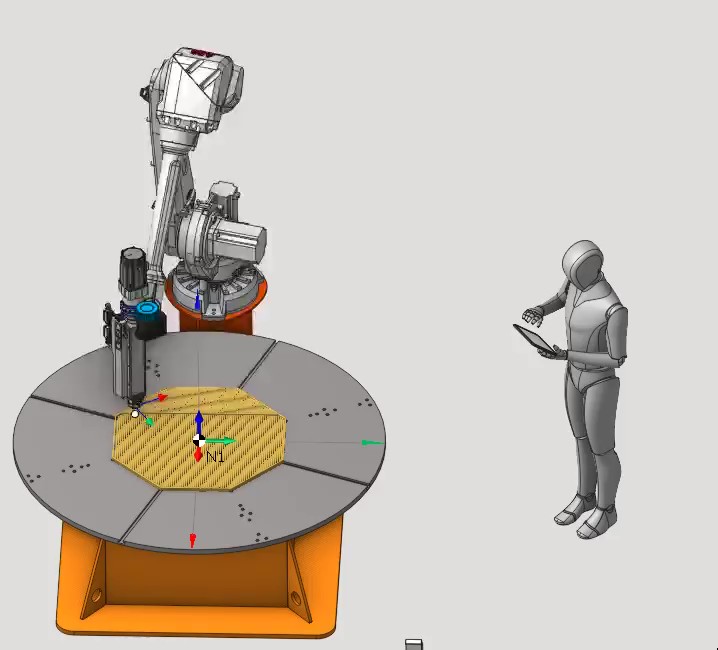

Cyber-Physical System Platform for Smart Manufacturing Systems

This project focuses on developing a Cyber-Physical System (CPS) platform for smart manufacturing systems based on the 5C model (Connection, Conversion, Cyber, Cognition, and Configuration). By integrating AI, IoT, digital twins, and real-time analytics, the platform enables intelligent decision-making, predictive maintenance, and adaptive process optimization. Leveraging Industry 4.0 and 5.0 principles, this CPS-driven approach enhances automation, human-robot collaboration, and sustainability in manufacturing. The goal is to create a resilient, data-driven ecosystem that reduces waste, improves productivity, and drives the future of autonomous, self-optimizing industrial operations.

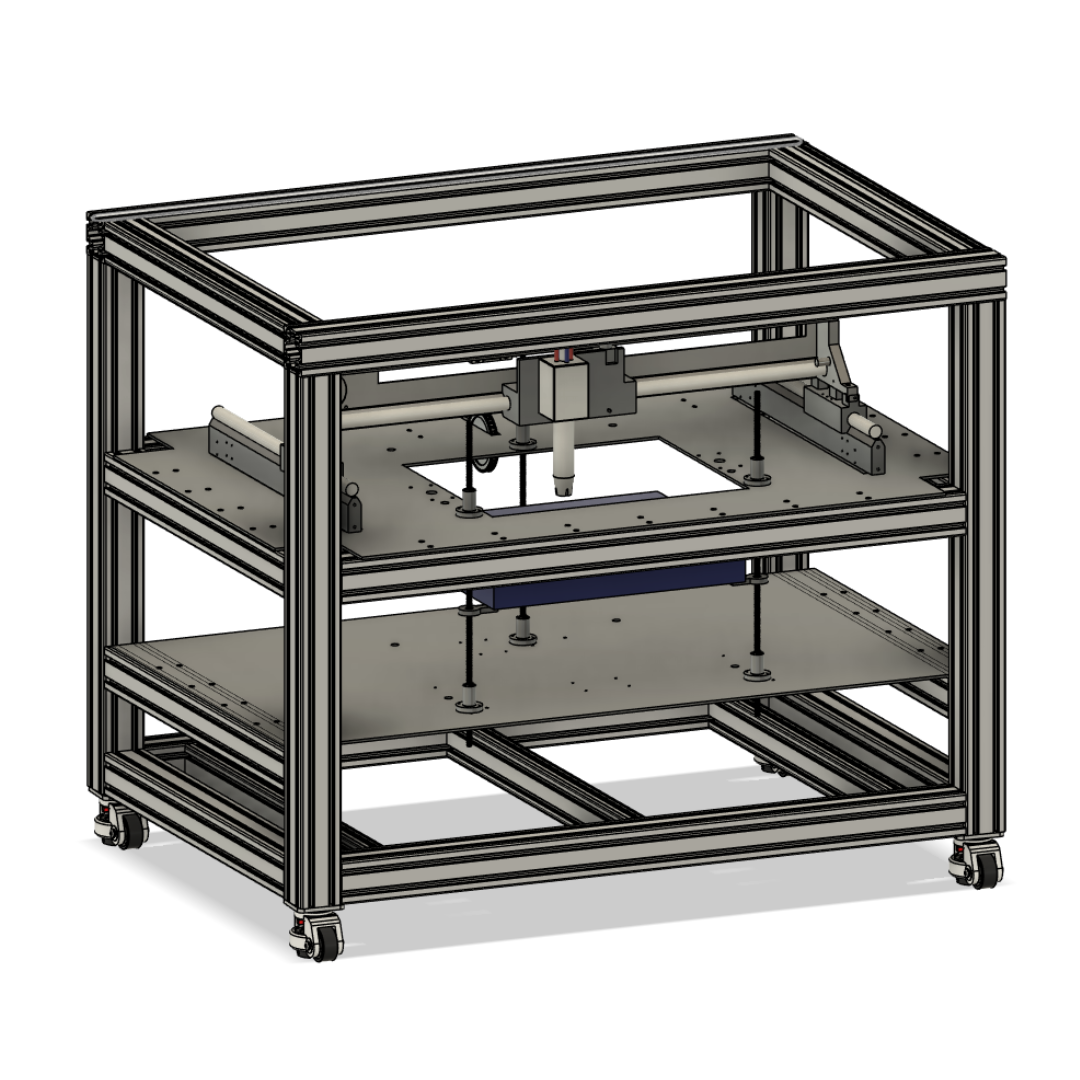

Additive Manufacturing System for Extreme Applications in Space

This project explores the development of an advanced additive manufacturing system designed for extreme environments, with a primary focus on lunar habitat construction. Leveraging robotic automation, in-situ resource utilization (ISRU), and Industry 4.0 technologies, this system aims to 3D print durable, self-sustaining structures using lunar regolith and advanced composite materials. By integrating cyber-physical systems, AI-driven process control, and autonomous robotics, the project will enable on-demand fabrication of resilient infrastructure for long-term human settlement and space exploration. This research lays the foundation for sustainable extraterrestrial construction, minimizing reliance on Earth-based resources and revolutionizing how habitats are built in space.

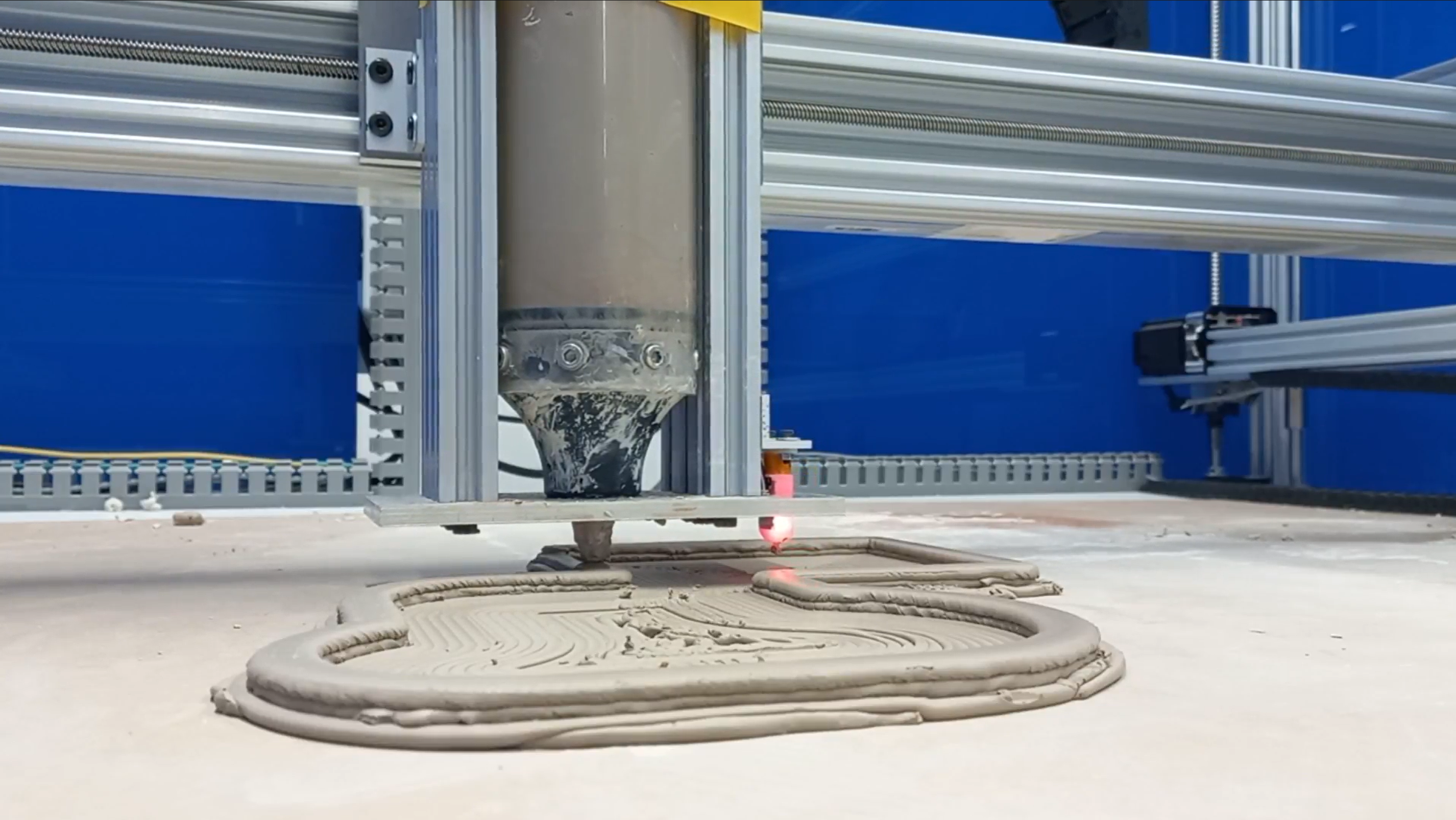

Canadian Sustainable Additive Construction Initiatives

This project is advancing eco-friendly 3D printing technologies for the construction industry by integrating system design, sustainable materials, and immersive AR-VR training. This project focuses on developing high-performance, low-carbon materials for additive manufacturing while designing smart, automated construction systems that enhance efficiency and reduce waste. Additionally, an AR-VR game-based training platform is being created to equip workers with hands-on experience in digital construction techniques, making sustainable building practices more accessible, engaging, and scalable for the future of construction in Canada.

Thermal Spray-Based Additive Manufacturing System for Sustainable, Low-Cost Metal Fabrication

This system enables rapid, open-atmosphere fabrication of large, high-performance components with tailored microstructures, achieving significantly higher deposition rates while reducing energy consumption and system costs. Applications span industries such as aerospace (e.g., lightweight turbine blades), energy (e.g., repair and remanufacturing of corrosion-resistant pipelines), and automotive (e.g., on-demand tooling). Currently in the computational modeling phase (CFD, FEA) and functional prototype development stage, this work aims to redefine scalable, cost-effective additive manufacturing. By merging advanced process optimization with sustainable practices, the system offers a pathway toward resilient supply chains and circular economies, positioning thermal spray AM as a solution for eco-conscious industrial production.

An Inclusive Learning Platform for Impaired Kids (DODO)

This project is breaking barriers in STEM education by making coding accessible to visually impaired (VI) children through an innovative, inclusive design. Traditional coding education relies heavily on visualization, creating obstacles for VI learners. By integrating computer vision, AI, and tangible paper blocky modules using the DODO model, this project enables hands-on, intuitive coding experiences that empower VI children to engage, create, and innovate. A working prototype has already demonstrated how these modules can be recognized as code, proving the potential of this design. Additionally, we are exploring plastic recycling in the DODO platform, ensuring that inclusive education is also sustainable and affordable, paving the way for equal opportunities in STEM for all.