Industrial

Robotics

We are driving the future of autonomous manufacturing by developing intelligent robotic systems and platforms that eliminate human intervention in dirty, dull, and dangerous tasks. We partner with the best for simulation RoboDK (www.robodk.com)

Target: Zero-Intervention

Using digital tools, computer vision, AI-driven machine learning, and advanced industrial robotics, our research focuses on creating smart, self-adapting automation that enhances safety, efficiency, and precision in production environments.

Key areas of innovation include autonomous assembly and disassembly, vision, and knowledge-based robotic systems, intelligent path planning, human-robot collaboration, automated repair, autonomous machine tending, and construction robotics (including mass-timber manufacturing, structural steel manufacturing, and additive construction). By integrating Industry 4.0 technologies and cyber-physical systems, we aim to build self-learning, fully autonomous robotic ecosystems that optimize productivity while ensuring a safer and smarter manufacturing future.

Related Projects

Generative Design and Robotic Fabrication of Mass Timber Building Components

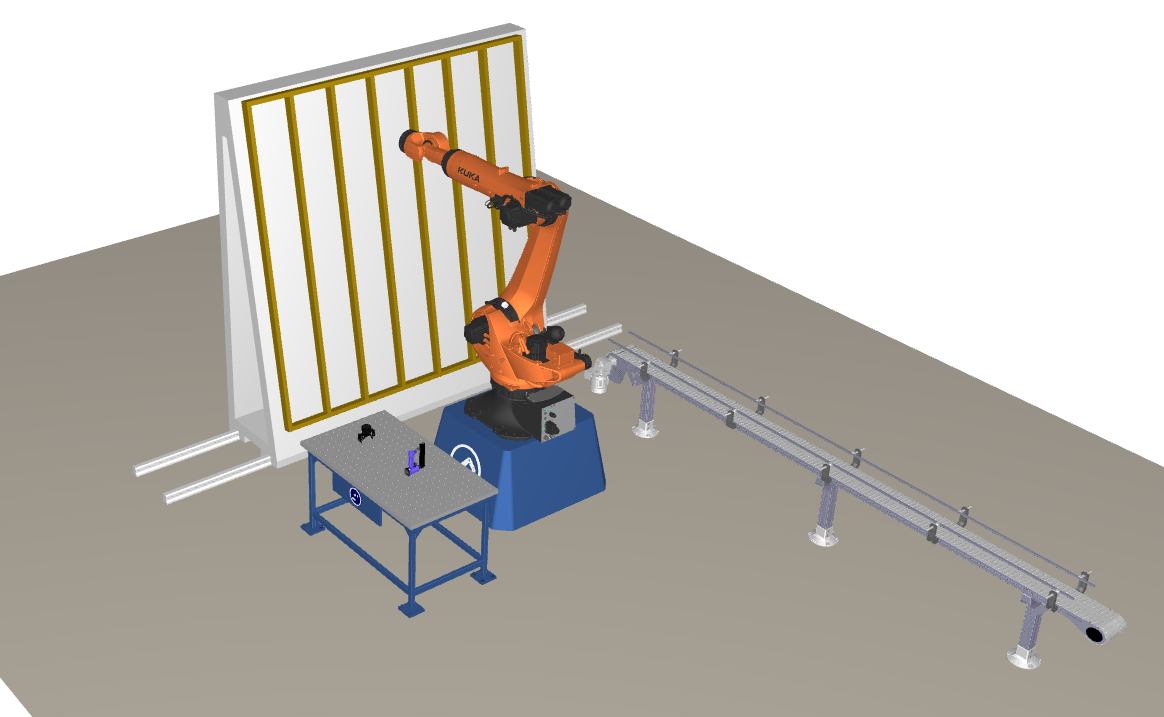

This project investigates the automation and robotization of the design and manufacturing stages of CLT panelized building components to identify a potential optimal prefabrication system by establishing a seamless design-to-fabrication framework. A design module is being prepared that can fetch preliminary designs of components from Building Information Modeling (BIM), including geometric and structural details, and compute the optimal designs based on material, manufacturing and assembly constraints. An automated planning module is under development that can optimize the robotic handling of CLT panels. It can take into account multi-tool end effectors of the robots and can plan time-energy optimal toolpaths and trajectories based on mechanical and safety constraints. These two modules combine to form the platform that connects the BIM models to the manufacturing robots.

Robotic Cell for Sustainable Offsite Structural Steel Construction

This project aims to develop a sustainable design-to-fabrication system for structural steel manufacturing via integrating industrial robot arms, advanced sensors, and intelligent algorithms to execute smart welding, automated cutting and screwing, automated assembly, and real-time quality inspection. The key steps of development in the proposed research attain three main goals: robotizing fabrication of structural steel components, optimizing material and energy usage, and automating inspection and quality control. The platform will feature a smart robotic work cell with proprietary software for toolpath planning and utilize sensor integration and machine learning algorithms for continuous control. Digital twin (DT) technology will be employed for decision-making management of the entire production process, from design to fabrication, ensuring real-time monitoring and optimization.

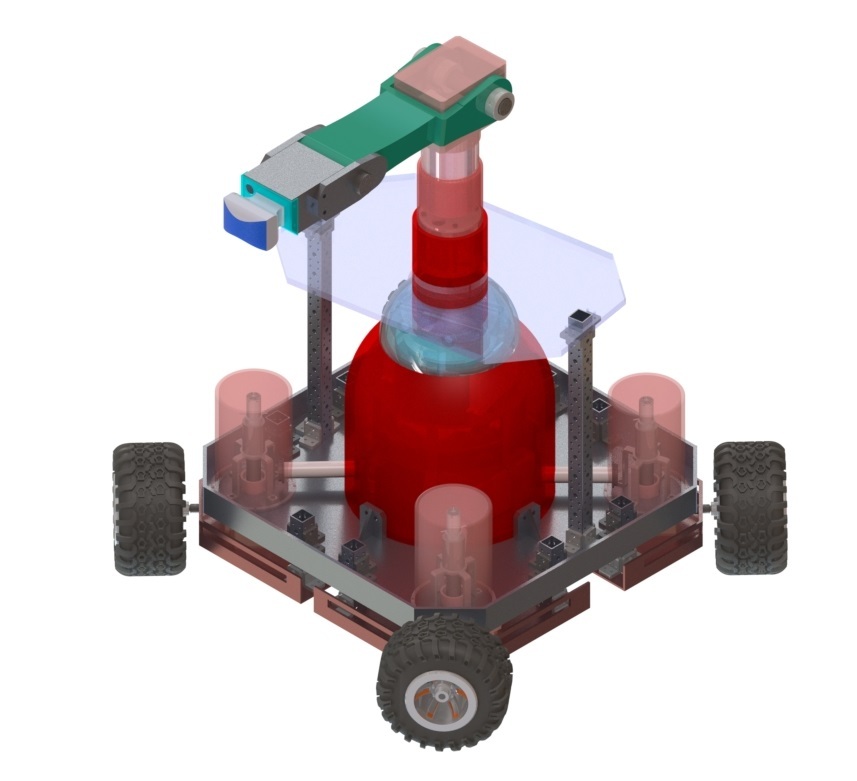

Mobile Robotic System for Inspection in Extreme Weather Conditions

The oil and gas industry demands reliable, autonomous inspection robots to operate in hazardous and extreme conditions, especially in Canada’s harsh winter climates, where temperatures drop to below -40°C. Traditional robotic systems struggle with outdoor mobility and comprehensive inspections in snow-covered landscapes. This project has developed a highly modular mobile robot that can be reconfigured into four models, tracked or omni-wheeled, with either a robotic arm or a PTZ camera system. This versatile robot performs visual and NDT inspections, navigates complex terrains and tight spaces, and ensures continuous monitoring of pipelines, storage tanks, and industrial infrastructure in temperatures ranging from -40°C to 60°C. This innovation enhances safety, efficiency, and reliability in extreme inspection environments.