Research

Themes

Our core research direction is to design, develop, optimize, and engineer intelligent and resilient manufacturing and production systems or processes aiming toward four significant research pillars:

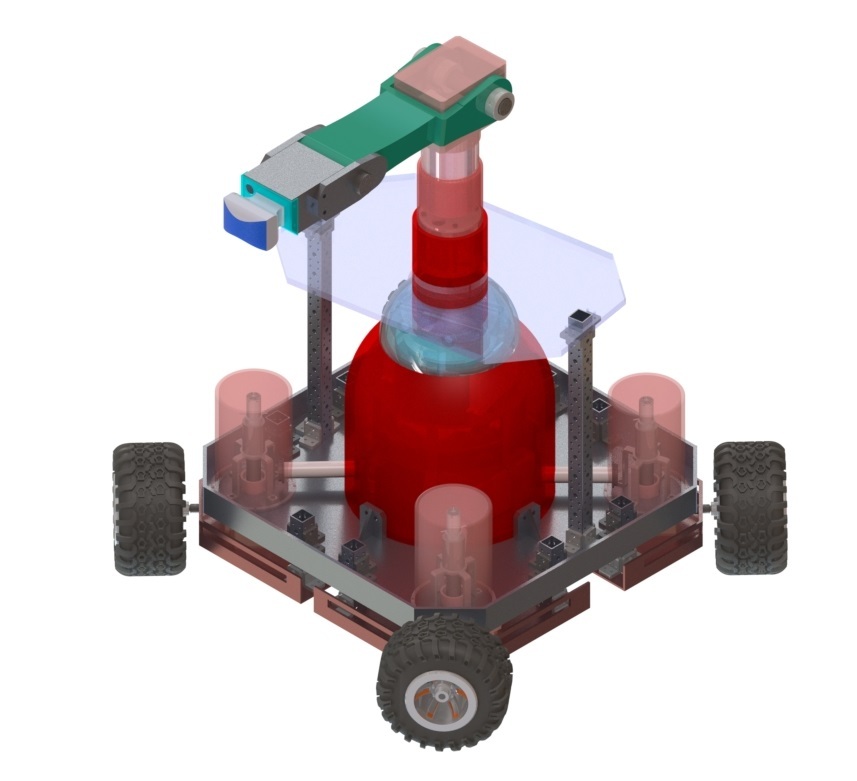

Zero-defect Research

Smart Manufacturing

Key areas include hybrid manufacturing (additive and subtractive processes), large-scale 3D printing (multi-material, freeform surfaces, recycled and abrasive materials, extreme environment applications), intelligent tool and process inspection, laser cladding, lean manufacturing, knowledge-based modeling, and topology optimization.

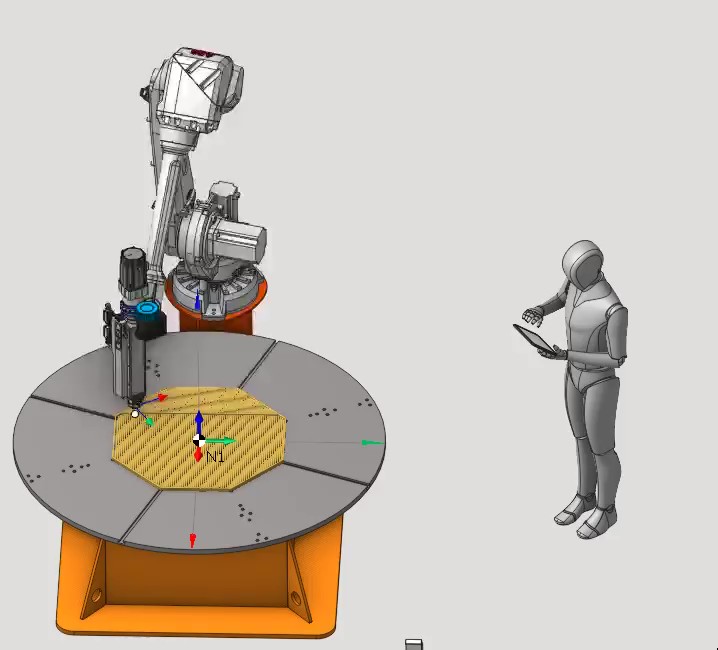

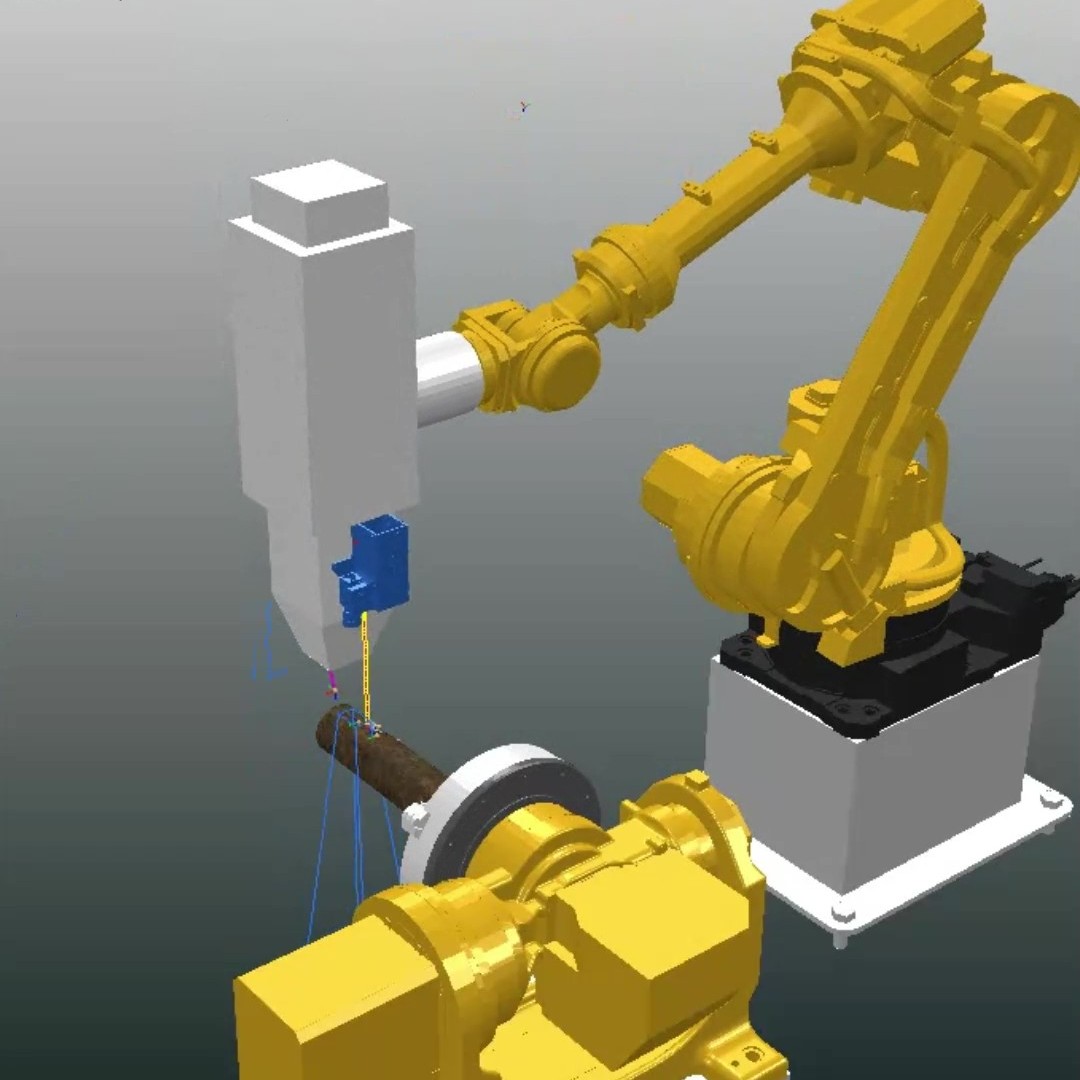

Zero-Intervention Research

Industrial Robotics

Key areas include autonomous assembly and disassembly, vision, and knowledge-based robotic systems, intelligent path planning, human-robot collaboration, automated repair, autonomous machine tending, and construction robotics (including mass-timber manufacturing, structural steel manufacturing, and additive construction).

Zero-Waste Research

Green Technologies

Key areas include autonomous repairing and remanufacturing of end-of-life metal components, plastic recycling for novel applications via additive manufacturing, and the design of intelligent, waste-free production systems.

Climate-resilience Research

Sustainable Production

Key objective is integrating Industry 4.0 technologies, automation, and AI-driven monitoring to develop high-efficiency production systems focusing on vertical farming and, more specifically, sustainable, environmentally friendly Aquaponics 4.0 systems and processes.