Green

Technologies

We are shaping a sustainable manufacturing future by integrating Industry 4.0 and 5.0 technologies to drive zero-waste production.

Target: Zero-Waste

Our research focuses on developing autonomous systems, intelligent machines, and digital tools for repairing, remanufacturing, and recycling (3R) of materials, extending the lifecycle of critical components while minimizing environmental impact.

Our work includes autonomous repairing and remanufacturing of end-of-life metal components, plastic recycling for novel applications via additive manufacturing, and the design of intelligent, waste-free production systems. By combining lean principles, advanced digitization, and smart automation, we are creating a closed-loop manufacturing ecosystem that optimizes resource efficiency, reduces waste, and accelerates the transition to a circular economy.

Related Projects

Plastic Recycling and Upcycling via Additive Manufacturing

Plastics are one of the most pressing environmental challenges, with billions of tons accumulating in landfills and oceans. This project, part of the Global Center for BioPlastics, focuses on recycling and upcycling bio-based plastics, along with all seven types of plastics (PET, HDPE, PVC, LDPE, PP, PS, and others), through a large-scale additive manufacturing and an autonomous production line. By integrating automation, AI-driven sorting, and advanced extrusion technologies, we aim to develop a fast, robust, and affordable recycling-to-production system that transforms plastic waste into high-value, sustainable products. This initiative supports Canada’s circular economy by reducing plastic pollution, cutting GHG emissions, and minimizing landfill dependency while pioneering a scalable, portable, and environmentally responsible manufacturing solution.

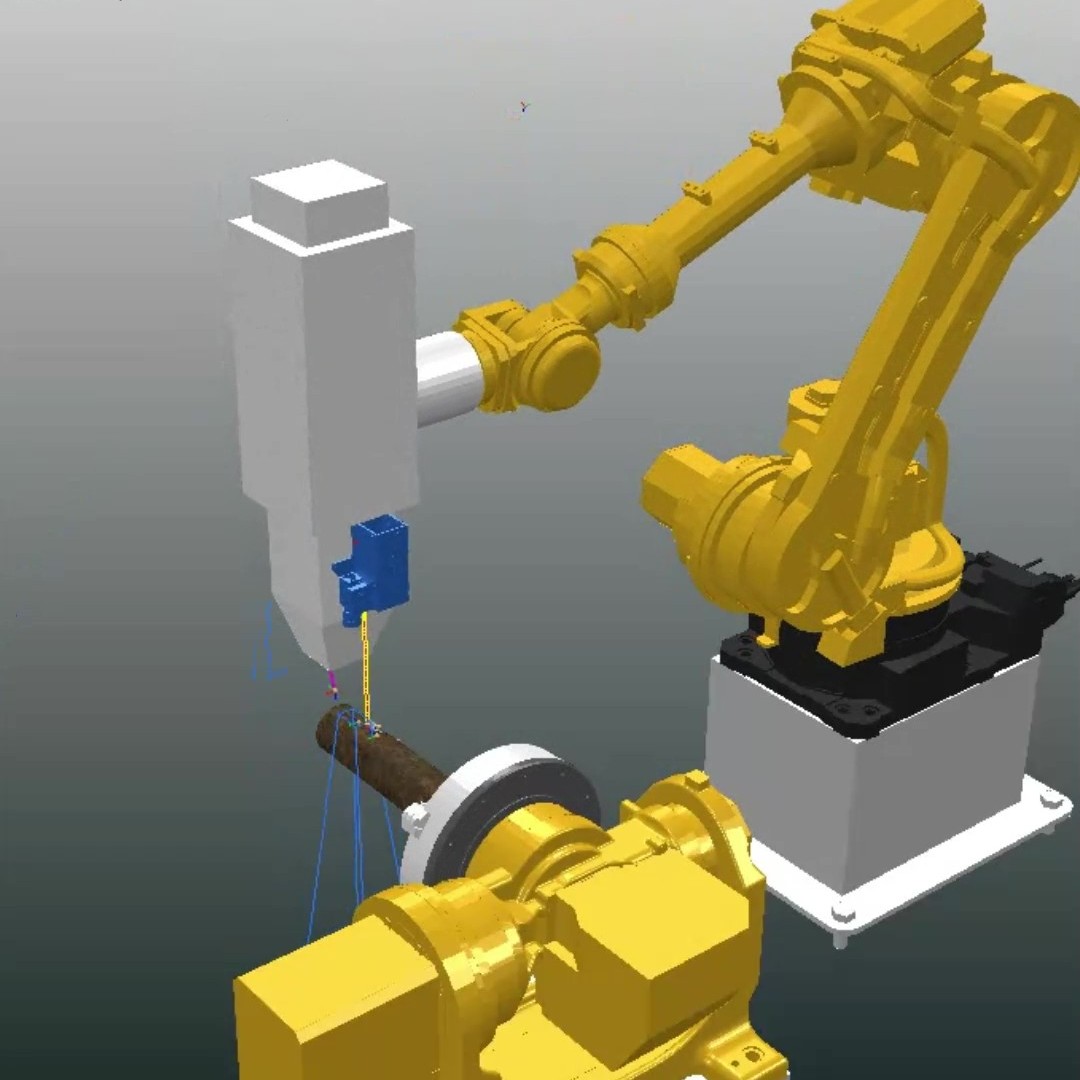

Wire-Arc Additive Manufacturing of Metallic Parts

In collaboration with InnoTech Alberta, this project is redefining Wire Arc Additive Manufacturing (WAAM) by developing new processes and advanced materials to extend the end-of-life of critical components, making products stronger, longer-lasting, and more sustainable. By integrating path planning, automated repair, and Industry 4.0 technologies, WAAM enables high-speed, large-scale metal printing with enhanced durability and customized material properties. A 6-axis robotic arm and 2-axis positioner, combined with a Cold Metal Transfer (CMT) welding torch, ensure precision-driven, adaptive manufacturing. This research drives the evolution of intelligent, autonomous, and repair-focused fabrication, reducing waste, enhancing material efficiency, and paving the way for next-generation industrial resilience.

Autonomous Repair of High-Value Components via Laser Cladding

This project explores advanced manufacturing solutions for repairing worn-out parts in extreme industries such as mining, aerospace, and oil sands extraction. By integrating laser cladding, additive manufacturing, and AI-driven 3D scanning, we aim to develop an automated, Industry 4.0-enabled repair system that restores parts stronger than their original state while reducing environmental impact. The research focuses on precise material deposition, tool path optimization, and stress management to enhance durability using wear-resistant alloys like Inconel and tungsten carbide. This innovation will revolutionize industrial repair, making it faster, cost-effective, and widely scalable across resource-based industries.